Use:

During the operation of the tape conveyor, due to the foreign matter in the material or the failure of the machine itself, the tape will be torn along the longitudinal direction of the tape for a long distance. With this repairer, the longitudinal tear of the tape can be quickly and effectively repaired. The factory can produce special specifications of repairing equipment according to the different needs of users.

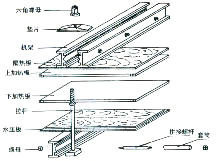

Schematic:

Electrothermal tape water cooling repairer technical parameters:

|

project/data/model

|

XBG-1

|

XBG-2

|

XBG-3

|

|

Repair the type of transport tape

|

Canvas, nylon, steel core rope transport tape

|

Canvas, nylon, steel core rope transport tape

|

Canvas, nylon, steel core rope transport tape

|

|

Repair shipping tape width(mm)

|

650-2200

|

650-2200

|

650-2200

|

|

Repair tape maximum break size(mm)

|

250×250

|

250×600

|

250×900

|

|

Electric heating plate dimensions(mm)

|

350×350

|

320×700

|

320×1000

|

|

Vulcanization temperature during repair145℃

|

0-200℃Adjustable

|

0-200℃Adjustable

|

0-200℃Adjustable

|

|

Total power(Kw)

|

1.91

|

3.5

|

3.5

|

|

Voltage(V)

|

380

|

380

|

380

|

|

Hot plate working surface temperature difference

|

±3

|

±3

|

±3

|

|

Vulcanization pressure(MPa)

|

0.8

|

0.8

|

0.8

|

|

The heating plate rises from normal temperature to vulcanization temperature(min)

|

<10min

|

<10min

|

<10min

|

Use the installation:

(1) Fill in the rubber in the repaired area (see the filling part in the vulcanization process of the tape joint. Or the demonstration by the service personnel of our factory when commissioning the equipment).

(2) Place the lower frame under the repaired area (all), under the rack, place the water pressure plate under the tape, and lower the heating plate (directly above the plate repairing place).

(3) Place the heating plate, the heat insulation board, and the upper frame alignment just below the repaired area.

(4) Install the tie rods, washers, nuts and tighten.

(5) Connect the electric control box and the power supply separately with one primary wire, and connect the upper heating plate with the secondary wire to correspond to the upper standard of the electric control box.

(6) Connect the water pump and the water pressure plate with a high-pressure hose, open the electric control box (see the XBG electric control box operation method for details), and fill the water pressure plate with water to the vulcanization pressure.